o remain competitive in global markets, ensuring quality standards in manufacturing is an important factor.

The tests that are essential for this must provide reliable results in a cost-effective and timely manner.

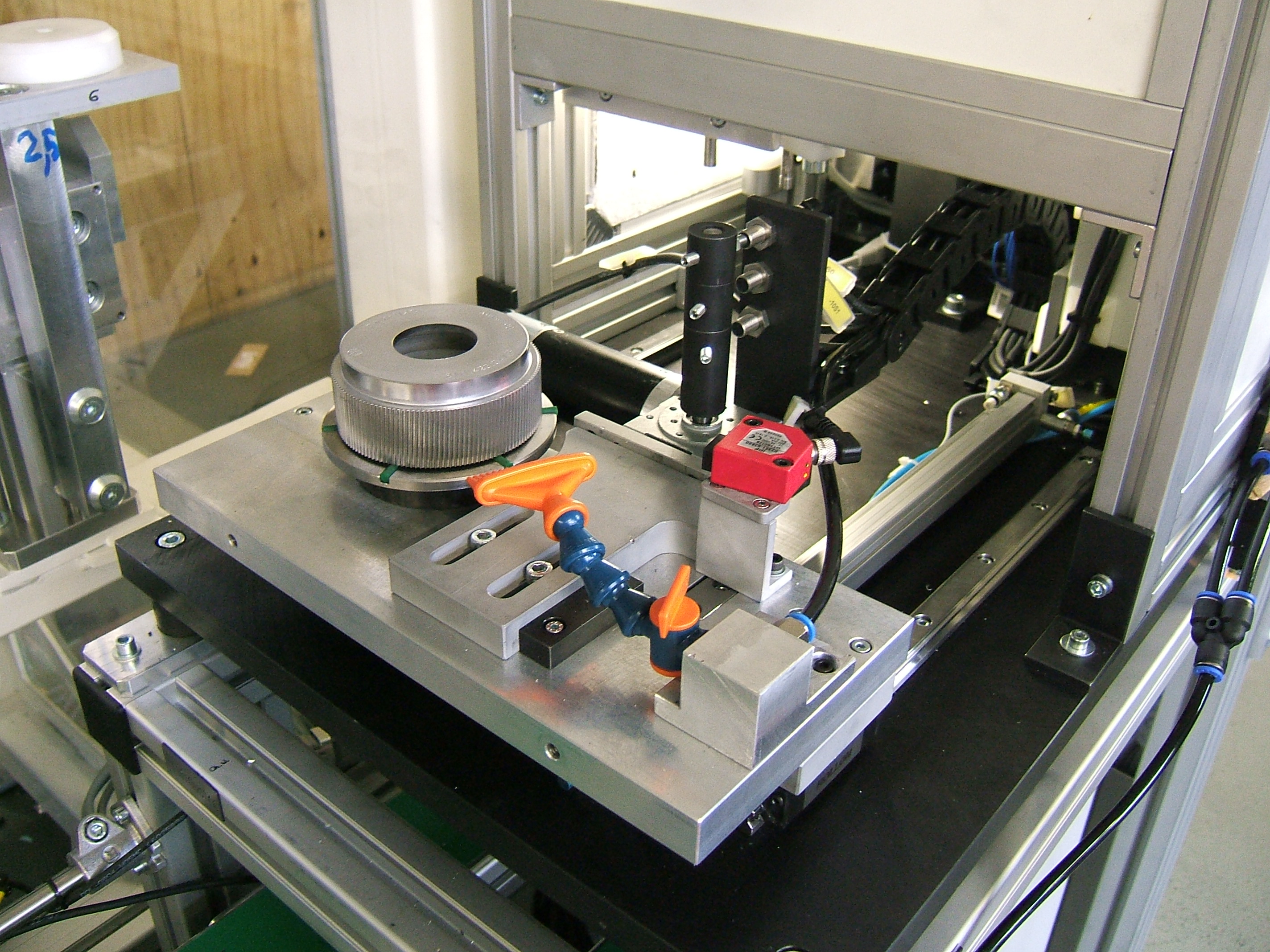

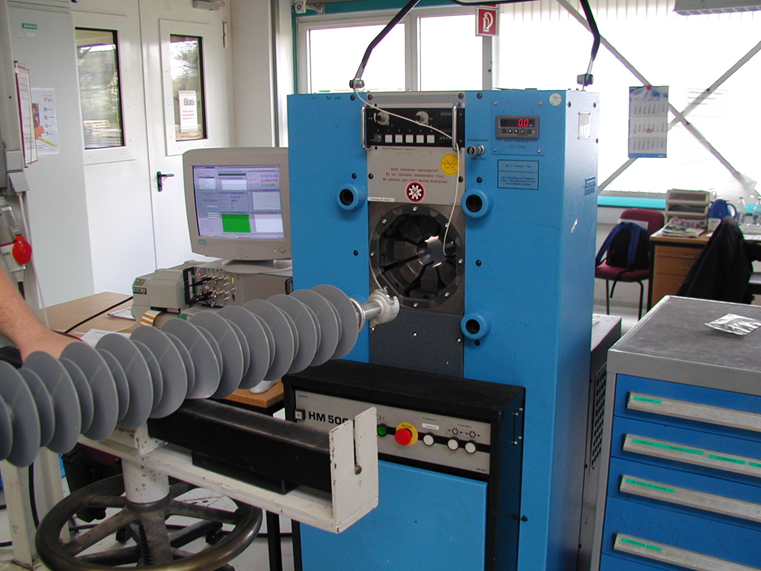

Quality control of dynamic, rotating and highly vibrating systems and components requires advanced and evolved testing methods, including vibration and sound measurements.

Simcenter Anovis is the solution to these challenges, automatically detecting and identifying product or process anomalies within seconds.

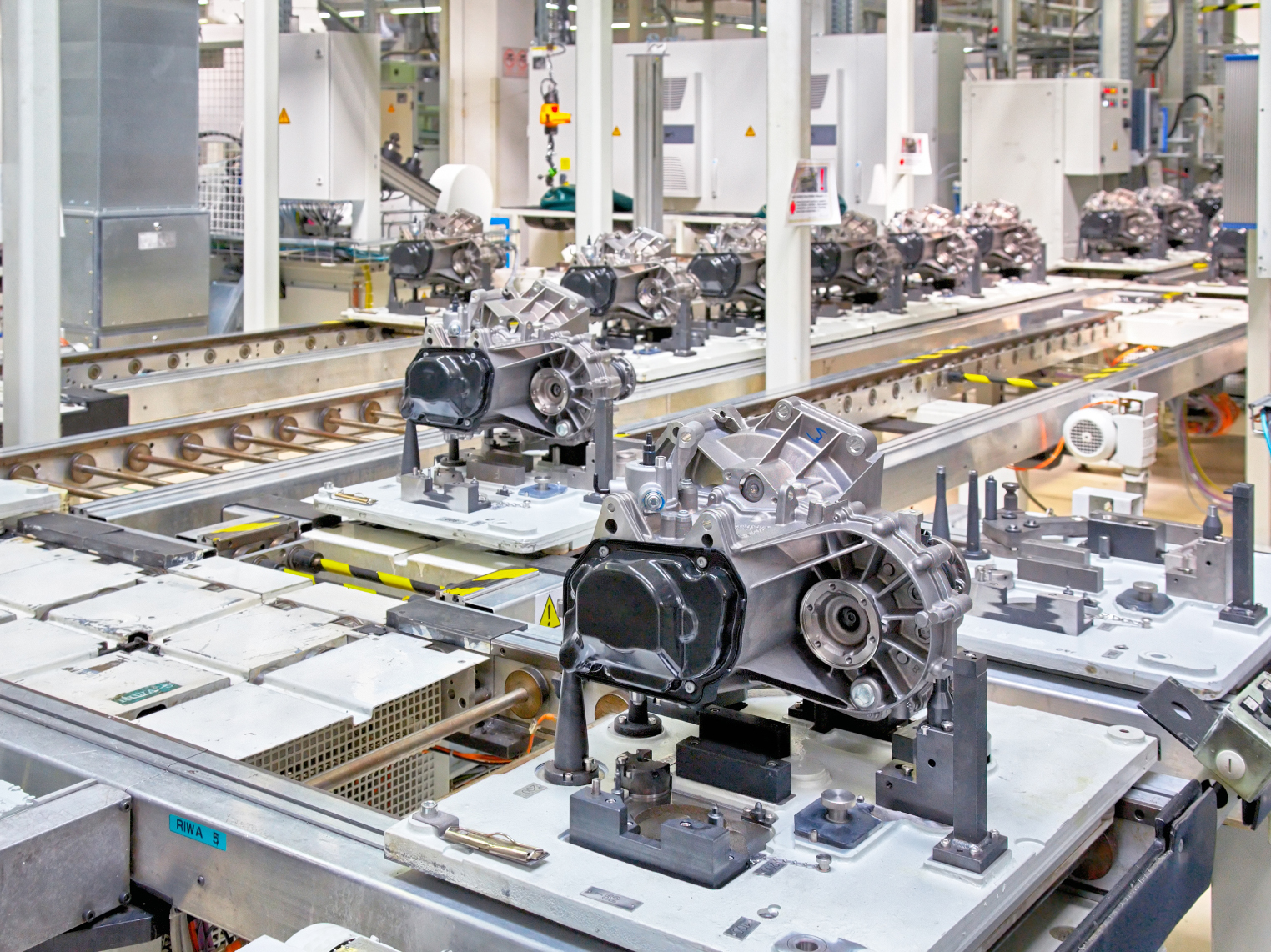

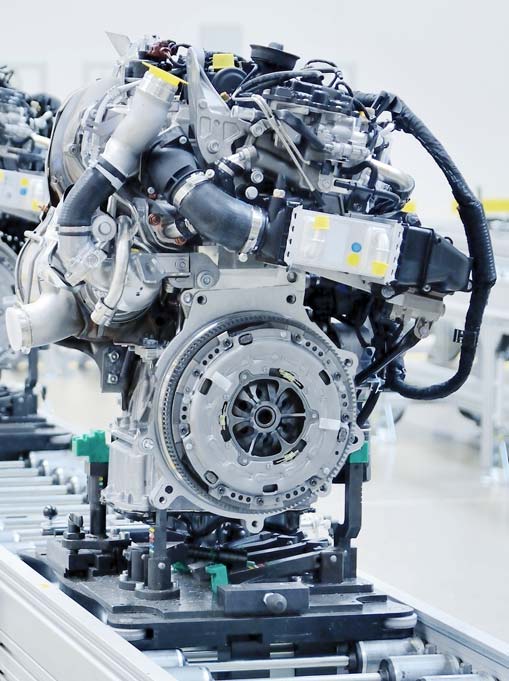

The standardized system can be adapted to a wide range of applications, e.g. in the automotive industry.

The possibilities range from EoL testing of rotating machinery and non-destructive component testing using acoustic resonance testing (ART) to production process monitoring with vibration and sound analysis.

The highly reliable world of the Anovis test equipment is diverse. We will show you more if you want!

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)