ith an accurate aerodynamic digital twin delivering performance prediction and design improvements in a short time, our simulation and testing solutions are key to designing better aircraft in the current landscape.

Simcenter Amesim enables the virtual integrated aircraft (VIA) approach to support your model-based systems engineering, modeling and simulation, verification and validation processes. This helps to optimize critical performance and reduce physical testing.

Simcenter Amesim helps you rapidly build digital replicas of aircraft systems and enables the VIA approach.

Why Simcenter Amesim for Aerospace and Defense?

1.

Supports the modeling of all types of aircrafts (airplanes, helicopters, rockets, satellites, spacecrafts …)

2.

Supports all functions and subsystems to address complex challenges

3.

Benefit from the Simcenter Amesim ecosystem to get well unified models

4.

Model-based systems engineering for the aerospace industry

Need more info?

Then let us show you how Simcenter Amesim help Airbus Helicopters reduce fuel system design cycle by a year.

Aircraft

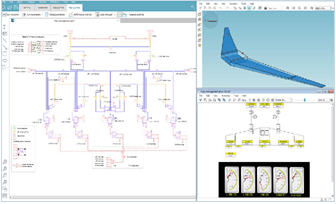

Digital twins of aircraft systems and how to create them

To enable the VIA approach,

Simcenter Amesim helps you rapidly

build digital replicas

of aircraft systems.

Ensure the comfort of passengers and crew by optimizing energy management,

air conditioning and ventilation. Account for

temperature, humidity, pressure

and change of pressure rate in dynamic

conditions. Design systems with higher efficiency, improved safety and lower weight.

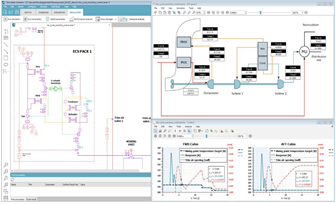

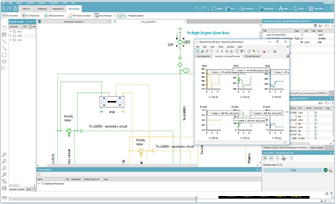

Create a more electric aircraft by optimizing

the electrical net- work and accounting for thermal integration. Analyze the impact of power network reconfiguration on

generators and loads in steady-state and transient phases.

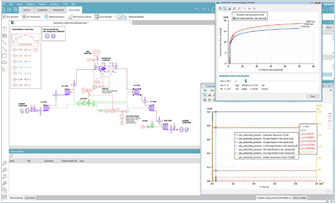

Balance the performance of conventional and innovative aircraft engine architectures: simulate their complete

thermodynamic cycles in various

operational conditions, accounting for environ- mental conditions and degradation of compressors and turbines, and integrate their equipment and consumers.

Analyze the behavior

of servo-hydraulic, electromechanical and electro-hydrostatic actuators

for primary flight controls, cable actuation for light aircraft,

and rotary actuators

for high-lift devices. Evaluate their performance by considering thermal

aspects and the integration with hydraulic or electri- cal systems.

Improve efficiency, reduce weight and energy consumption of the fuel systems

while satisfying certification requirements.

Optimize fuel pressurization, fueling, refueling and defueling of reservoirs

with complex shapes while accounting for aircraft attitude, acceleration, wing bending or twisting.

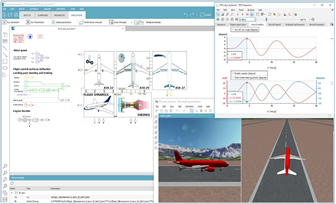

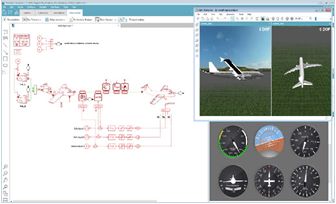

Optimize aircraft stability and improve early

stage autopilot controller design. Account for mass, inertia and center of gravity position

to assess handling

qualities during the flight mission.

Simulate mechanical, fluid, electrical and thermal aspects. Analyze system sizing options under various operating condi-

tions. Meet shock absorber requirements, optimize the kinematics for extraction and retraction,

as well as improve braking and steering systems.

Simulate hydraulic systems’ behavior for different sizing scenar- ios and flight missions. Integrate your hydraulic systems

with flight controls, electrical or

landing systems, to assess overall aircraft performance. Estimate the

system’s degraded perfor- mance to meet certification requirements.

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)