peppe

Chengdu: Multi-attribute balancing for better electric vehicles

In the first blog of this series, we discussed the new engineering center in Chengdu, China — an innovative leader when it comes to vehicle electrification. We have since discussed various labs, including the ADAS, HIL and battery simulation labs located at this advanced new facility. Today we focus on the Chengdu multi-attribute balancing (MAB) lab and how it can help design teams build their electric vehicles early on and boost performance. The MAB lab helps to balance and optimize seemingly conflicting performance requirements of individual attributes.

[TECH TIP] Component-based Transfer Path Analysis (TPA) explained

An educational video explaining the Component-based Transfer Path Analysis (TPA) method. By isolation components and combining TPA data with test and simulation data in a modular way, engineers can predict full vehicle NVH in any configuration. Component-based TPA speeds up the development process, allows for better component-supplier communication, and helps avoid costly troubleshooting. Watch the video.

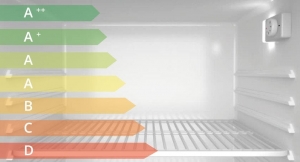

Effizientere Kühlschränke mit 0D/1D-Simulation entwickeln

Zu den verwendeten Strategien gehören die Auswahl der Komponenten, die Änderung der Kontrollstrategie oder die Variierung der Kältemittelflüssigkeit.

Wir sehen heute, wie die modellbasierte Simulation von Simcenter Amesim genutzt werden kann, um die Entwicklung eines immer ökologischeren Kühlschranks zu fördern.

[VDL] Aiming for zero-emission buses

Anouk Hol, Aerodynamics and Energy Specialists at VDL Enabling Transport Solutions, explains how Simcenter Amesim help optimize component design and vehicle energy management of electric buses. Watch Video

Producing Food and Beverages in the Digital Age

My earlier post, Surviving the New Competitive Landscape in Food and Beverage, introduces the need for companies to leverage digitalization to compete in today’s rapidly evolving industry. The post explains that the market is changing, challenging the status quo as barriers to competition drop and small, innovative companies begin to take hard- earned market share away from traditional leaders.

Commission your machine before building a prototype

Overcoming 30-year-old legacy On a client factory floor after erecting a new machine over two weeks, the senior start-up manager and his team are busy launching cold & hot testing. The next step in the commissioning phase is performance testing. The anticipation in the air is palpable. This machine, built to unique requirements, invokes special control algorithms (PLC code). Ensuring the smooth functioning of several physical domains (pneumatics, hydraulics, mechanics, and electrical) posed challenges of epic proportions. The automation engineer reflects on how the unavailability of the iconic controller delayed automation and sensors’ calibration.

All you need to know about vehicle active sound design

The growing electrification trend in the automotive industry is noticeably reshaping vehicle development. This new power train concept has a direct impact on other vehicle performance aspects and introduces new challenges. One of the main concerns that is even changing the legal framework on the international level is the acoustic characteristics of these vehicles.

This is the moment when the rising technology called ”active sound design” comes into play.

[White Paper] Efficiently combining test and simulation for model-based development

Find out all there is to know about System Simulation

Reach 50% efficiency of your off-road engines with system simulation

Fit with total cost of ownership objectives complying with emissions regulations. Even if we are currently hearing a lot about electrification, off-road machines remain mainly powered by the internal combustion engine (almost nearly 100% for construction equipment). However, pollutant emissions from combustion engines significantly contribute to air pollution by emitting carbon oxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter.

English (UK)

English (UK)  Deutsch (Deutschland)

Deutsch (Deutschland)