The newest update of Simcenter Systems simulation release 2310, has arrived and it’s packed with great new features to help you tackle your everyday challenges easily. Save time at every step of the engineering process by optimizing your workflow, and managing complexity to keep pace with innovation. This blog highlights some of the new features in this release, which include Simcenter Amesim, Simcenter Flomaster, and Simcenter System Analyst.

Battery

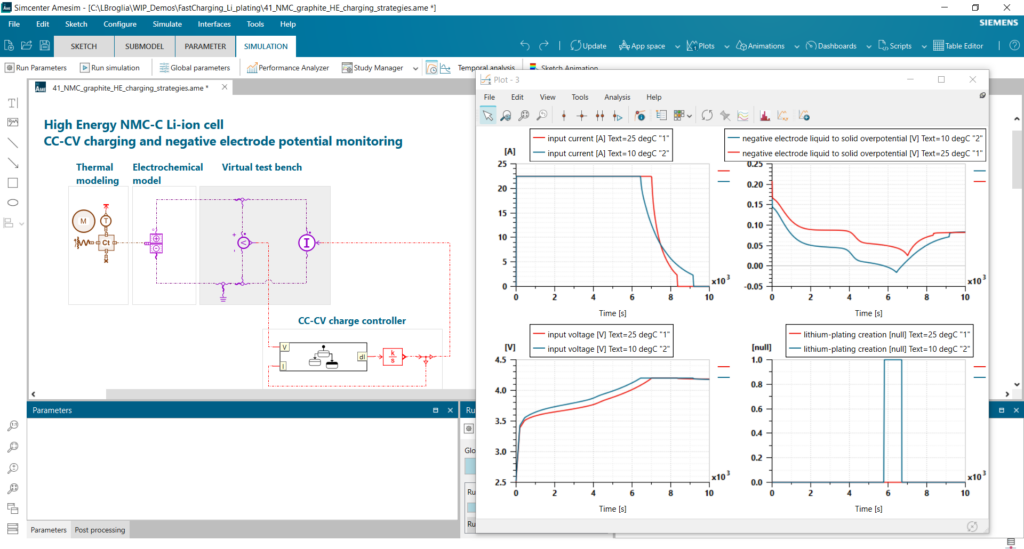

With the shift to electrification, the need to simulate batteries, fuel cells, and efficient pipelines is critical. In Simcenter Amesim 2310 an upgraded refined particle meshing method and a dedicated variable for lithium plating detection, accurately estimates voltage and assesses Lithium plating risk in various scenarios, including fast charging at different temperatures.

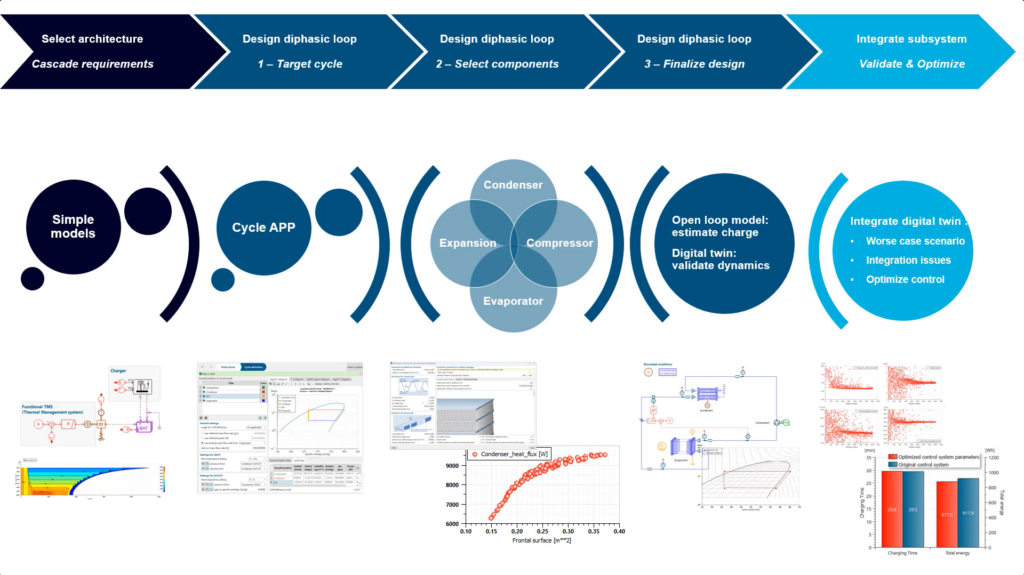

The new Battery Thermal Management System demoset available in Simcenter Amesim 2310 is perfect for teams designing thermal management systems. It offers a clear workflow to design your thermal technology from end-to-end, leveraging advanced integrated tools and resources.

Energy transition

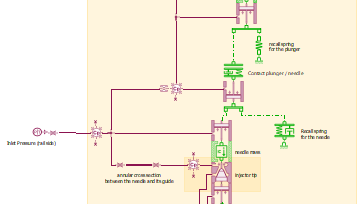

In 2310 release, we are taking a step forward and are expanding the Simcenter Amesim’s hydrogen injection demo by including a detailed model of injector and pressure regulator for hydrogen injection systems. This model demonstrates that the existing Pneumatic and Pneumatic Component design libraries can be successfully used to create detailed models and have important insights into specific behaviors of hydrogen injection systems.

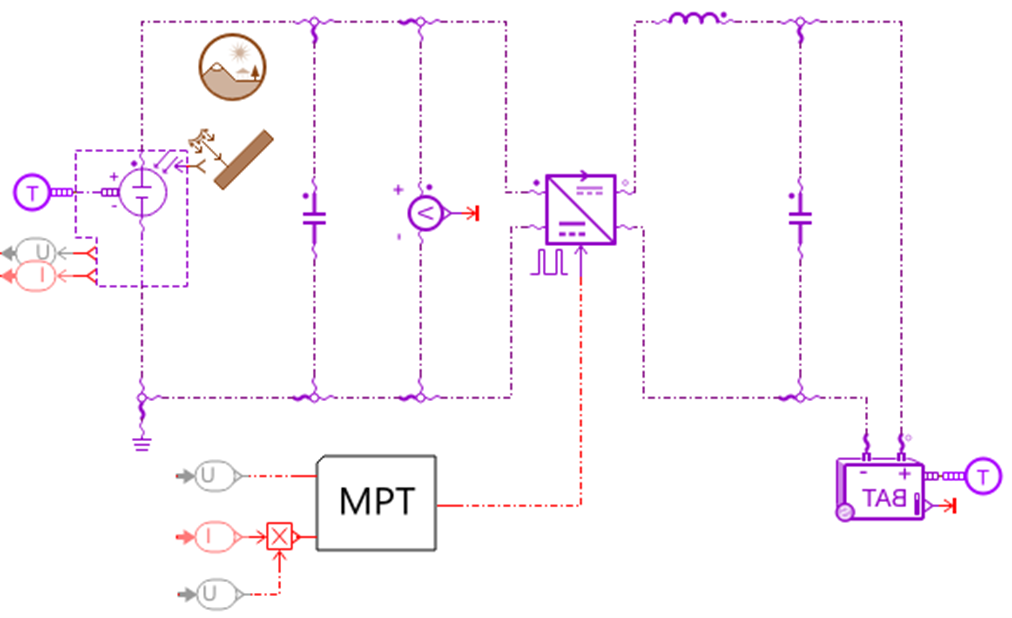

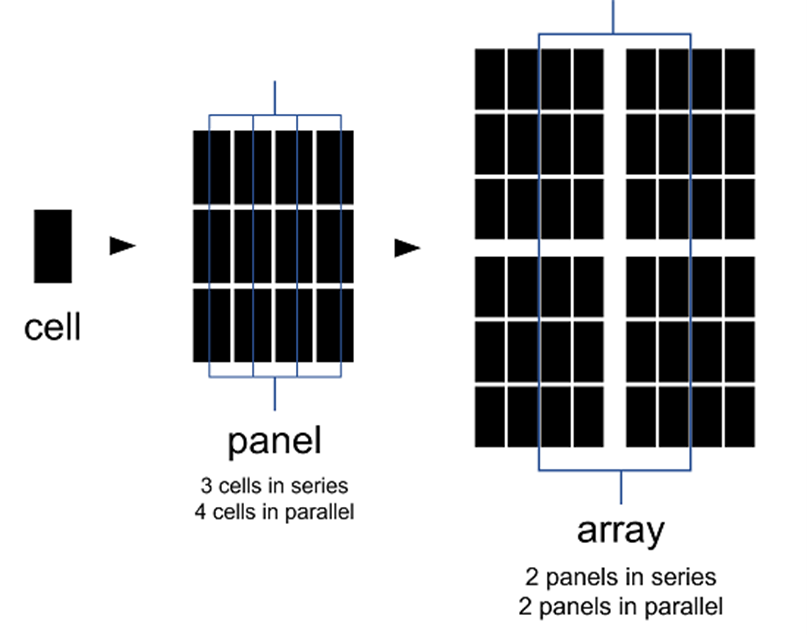

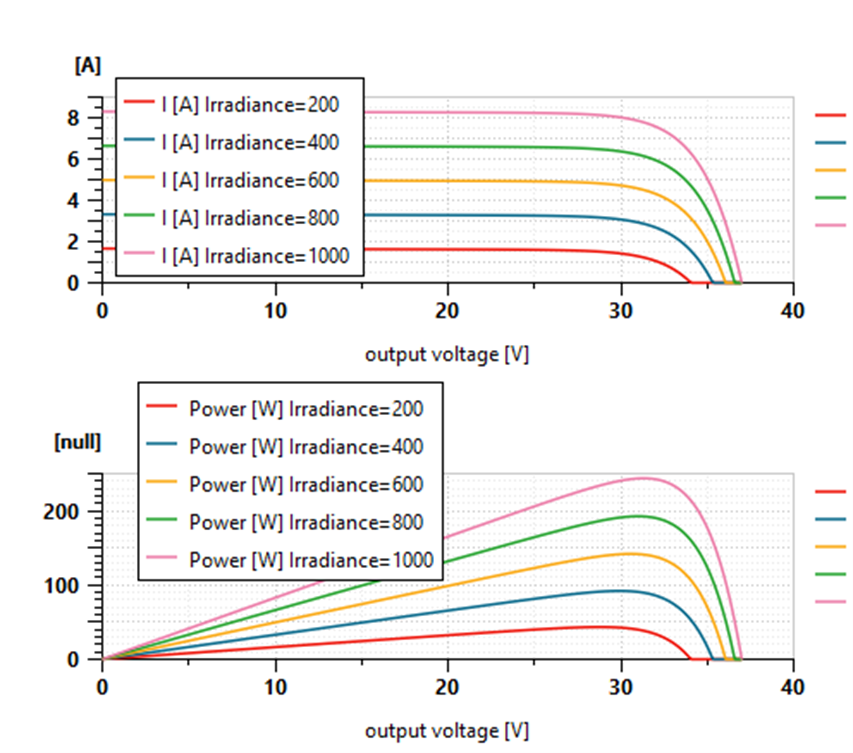

With the introduction of the 2310 version, solar energy engineers can perform precise analyses on photo-voltaic solar units, including energy production and revenue forecasting, thanks to the improvements made to the solar panel. These enhancements comprise a simple definition of model parameters that can be found in datasheet information. Additionally, engineers can scale-up photo-voltaic cell units into solar panels and arrays effortlessly.

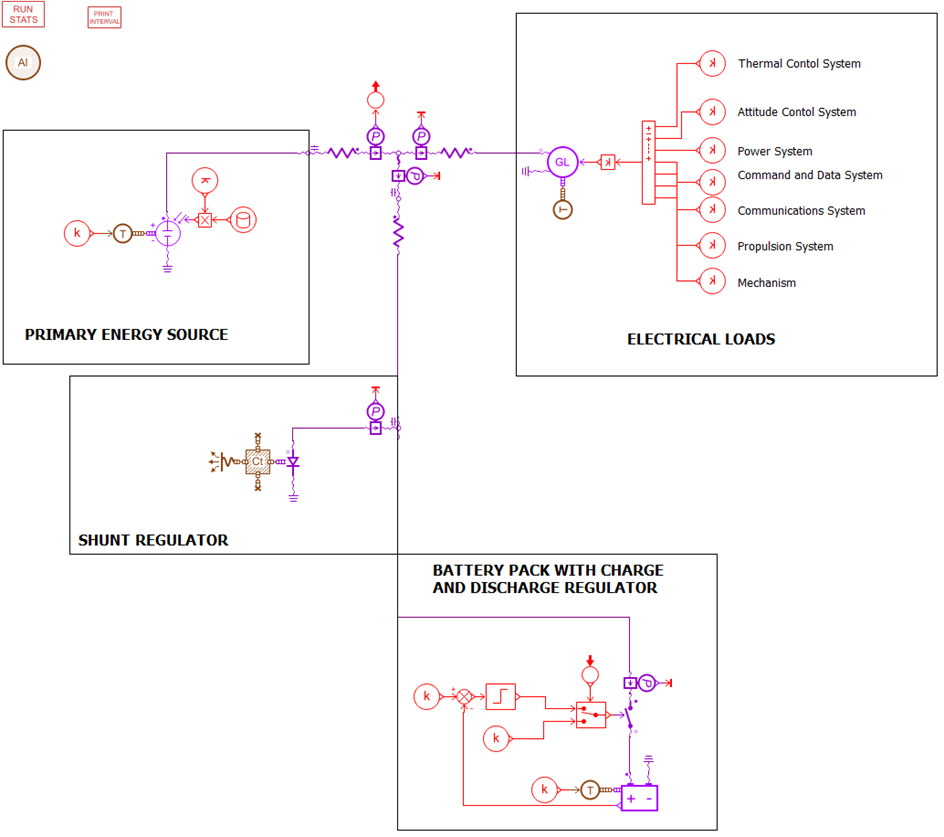

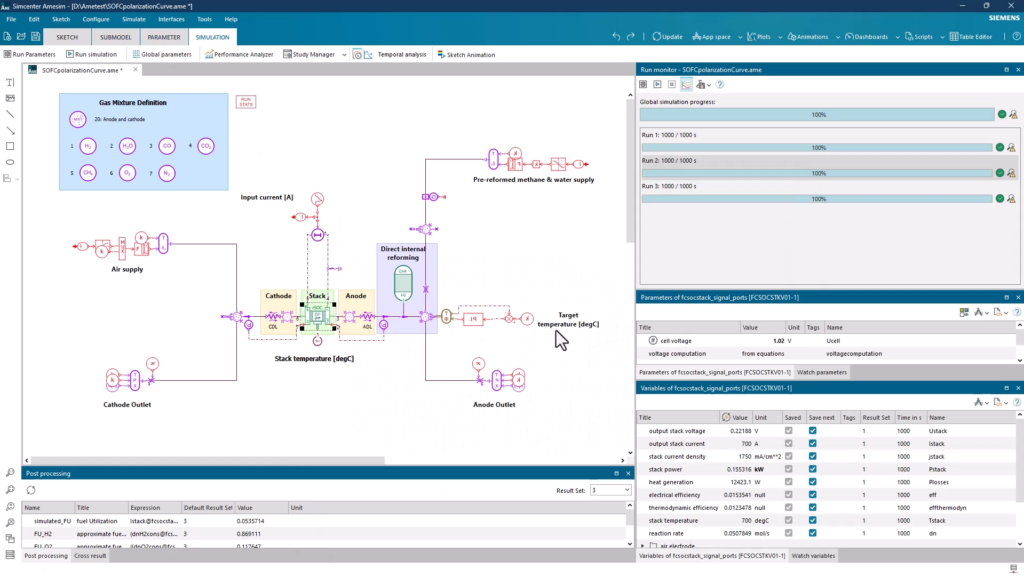

Simcenter Amesim is now offering a new reversible Solid Oxide Fuel Cell framework that includes reformers and a basic demonstrator. This framework is a comprehensive solution to tackle the challenges faced by the energy sector in terms of decarbonization. The predictive models incorporated in the framework enable engineers to evaluate the performance of the Reversible Solid Oxide Cells under various pressures, temperatures, and species concentrations, including start-up and shutdown sequences. With the new components, engineers can build Power-to-X systems with endless possibilities. They can size the components, optimize the architecture, and define the control strategies that account for the variability of green energy supply, costs, and CO2 emissions.

Automotive and transportation

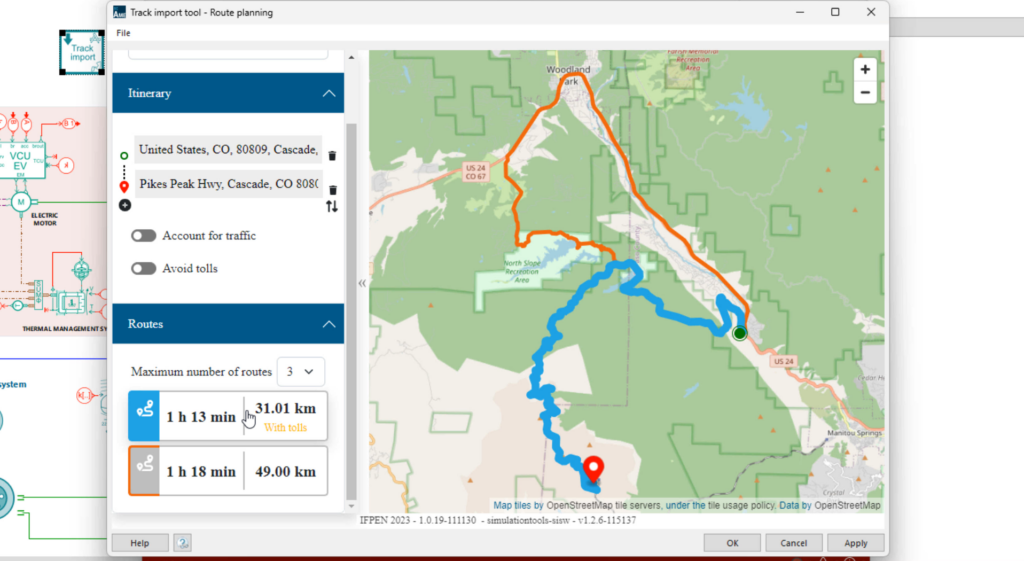

One important challenge for vehicle engineers is to understand how vehicle designs will behave in real-world scenarios whether on or off-road. The Simcenter Amesim Track Import Tool features a new 3D road generator; powered by the HERE map database, it allows the generation of 3D roads from shared worldwide GPS data for simulation with different driving profiles.

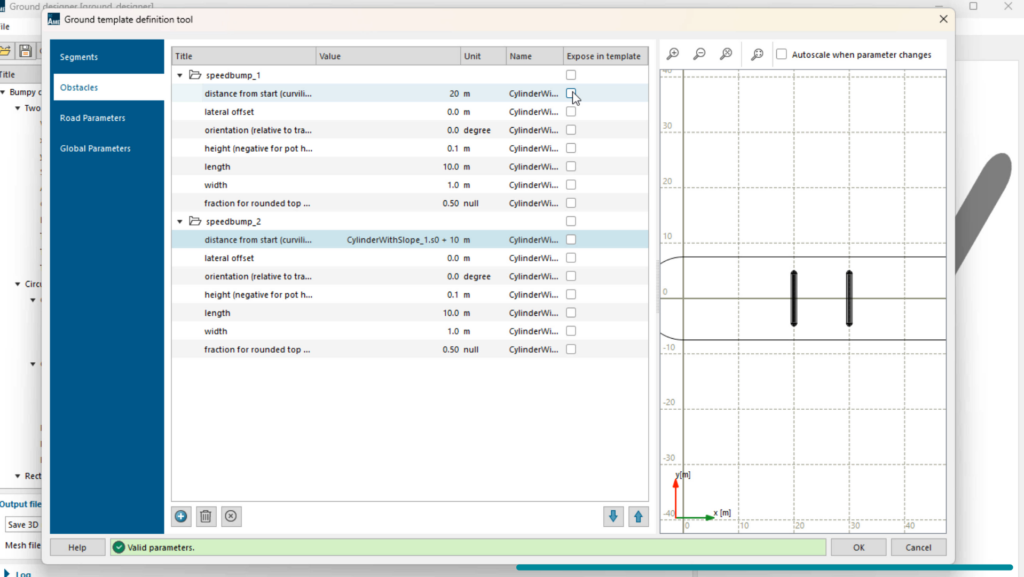

Simcenter Amesim’s new Ground template visual editor provides a tool to design test ground templates for cars and off-road vehicles. This allows chassis design engineers to easily create various types of proving grounds, including obstacles of different shapes, heights, and lengths. Additionally, the tool can run batch simulations to enhance the value and ease of testing.

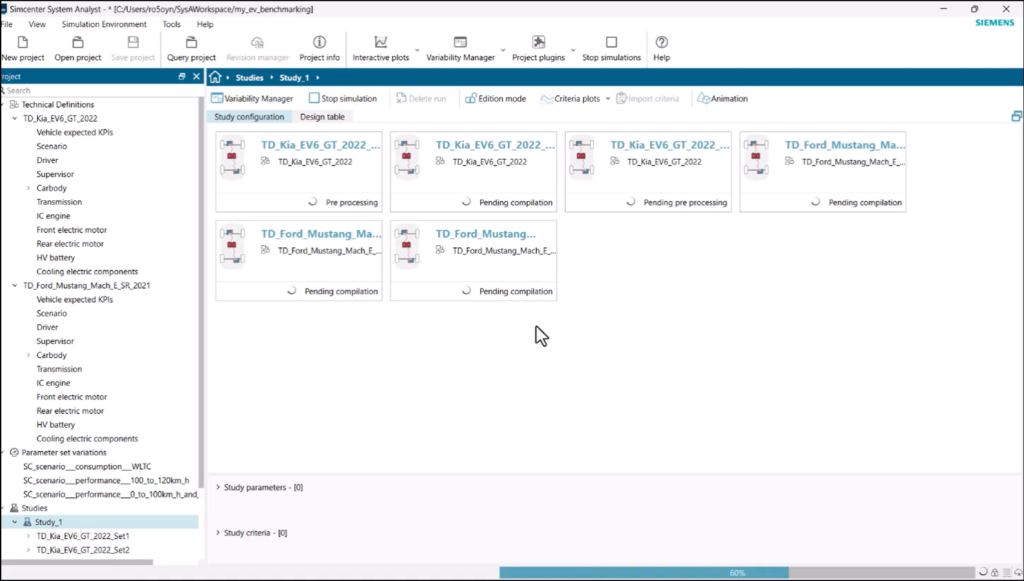

The new Electric Vehicle database in Simcenter System Analyst is beneficial for CAE methodology groups who want to understand how the software works and what information it provides. The database contains various electric vehicle configurations that can be utilized for testing and using Simcenter System Analyst in a practical and mainstream application. This means that the user can simulate an existing electric vehicle with realistic parameter values, query a vehicle configuration with a single click, compare simulation results with publicly available information, and perform ‘what-if’ scenarios by switching components between vehicles, changing driving scenarios, or adjusting parameter values.

Aerospace and defense

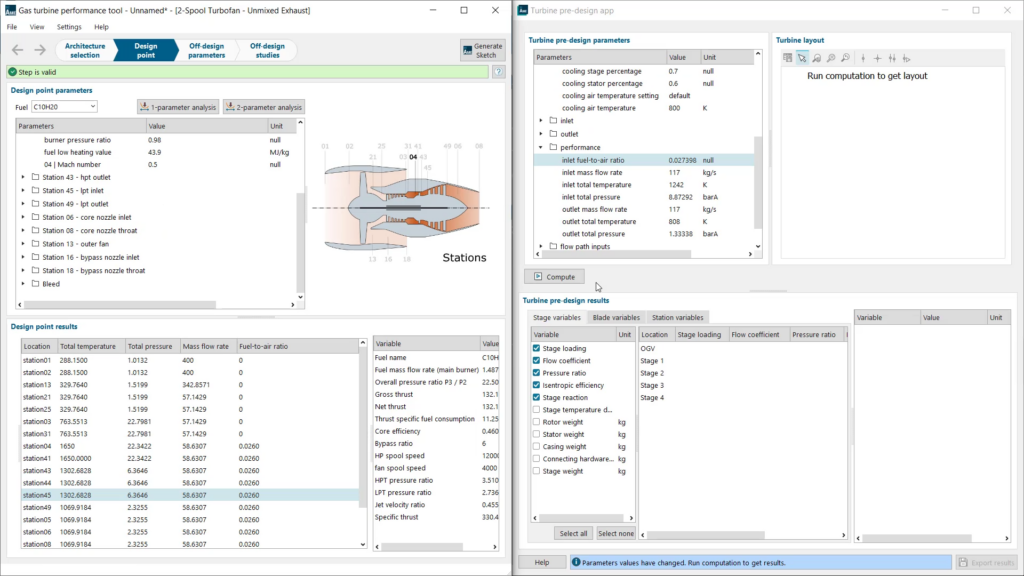

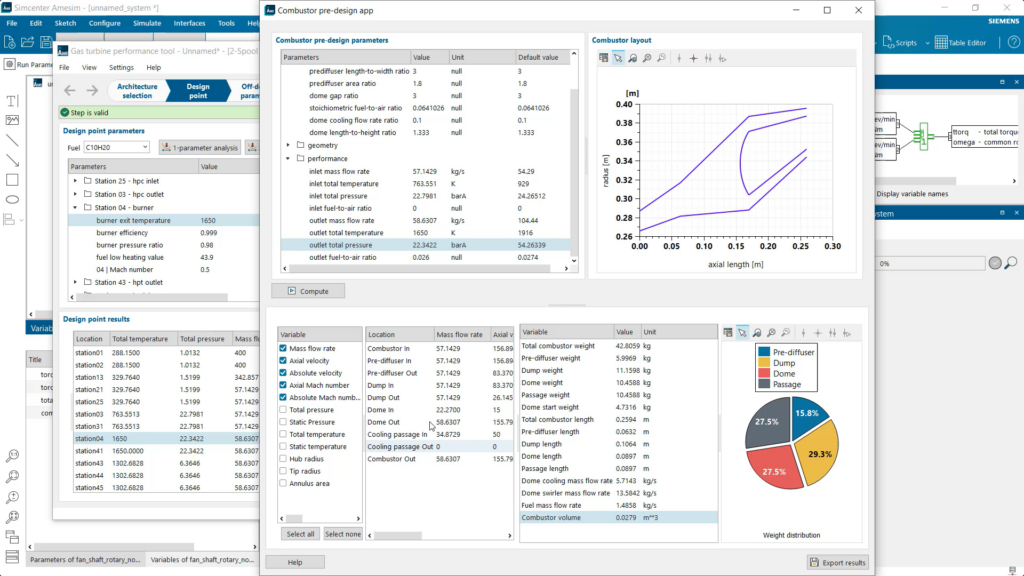

Simcenter Amesim 2310 offers turbine and burner predesign apps that help gas turbine and engine performance engineers extract necessary information before CAD models are available. This enables engineers to evaluate design weight penalties, generate essential data, and understand transient behavior of the engine. These apps also provide clear displays of turbine and burner layouts, making the design process more accessible and efficient.

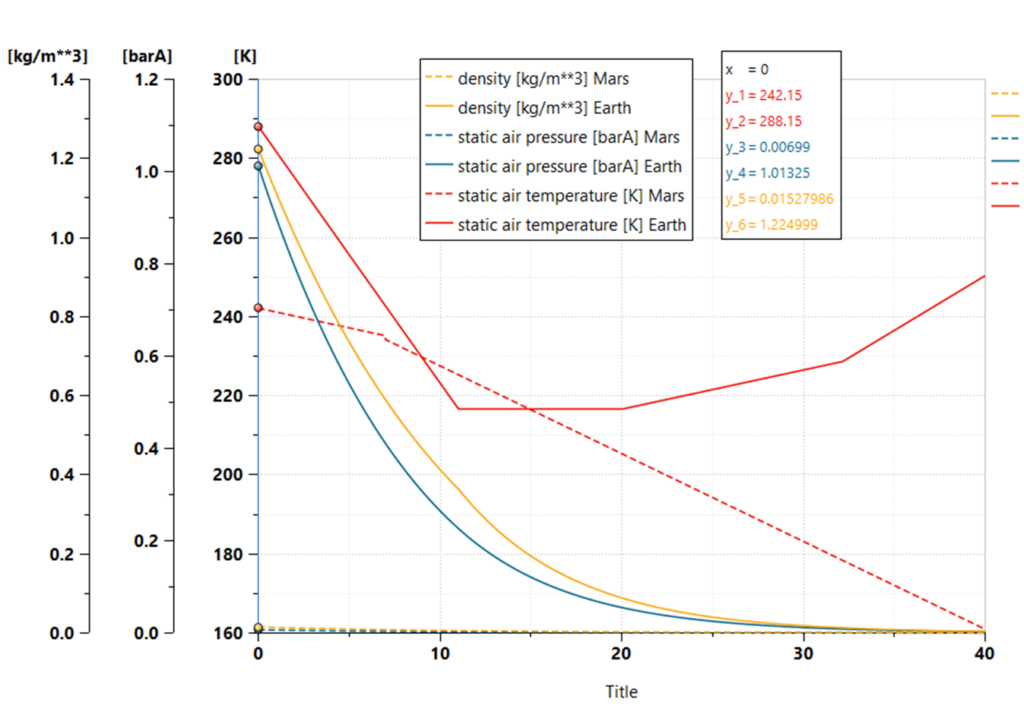

Although the first attempts to send landers to MARS date back to the 70s, in the last decade we have seen an increase of successful missions that sent landers, rovers and even helicopters on the ground of mars. To support what we could call a rush to MARS, we have implemented in Simcenter Amesim 2310 a pre-calibrated Martian atmosphere that allows flight dynamics engineers to accurately asses vehicle flight performance on MARS. More specifically, engineers can accurately calibrate their guidance, navigation, and control systems and find the optimal tradeoffs.

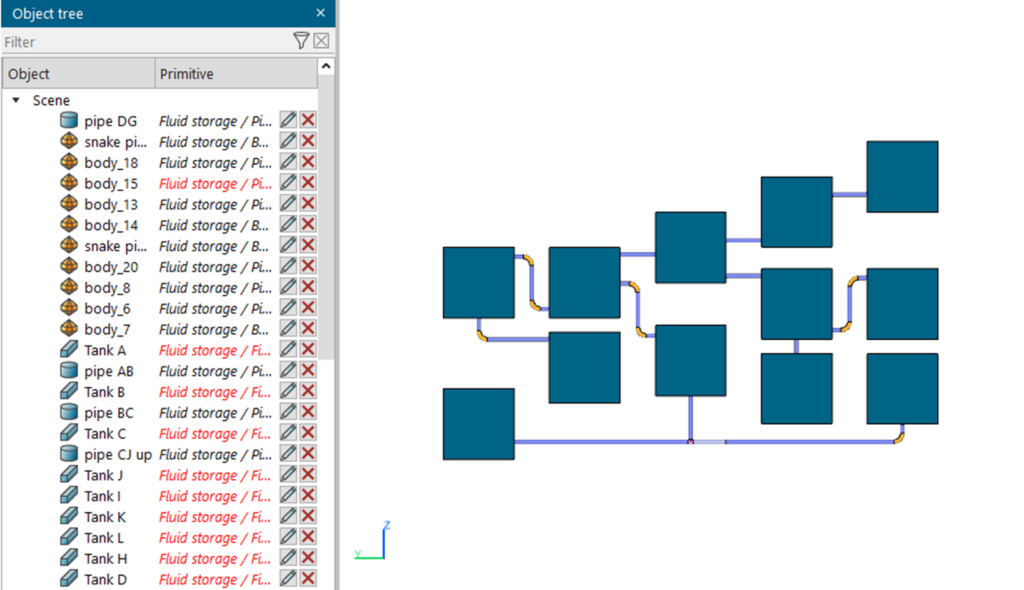

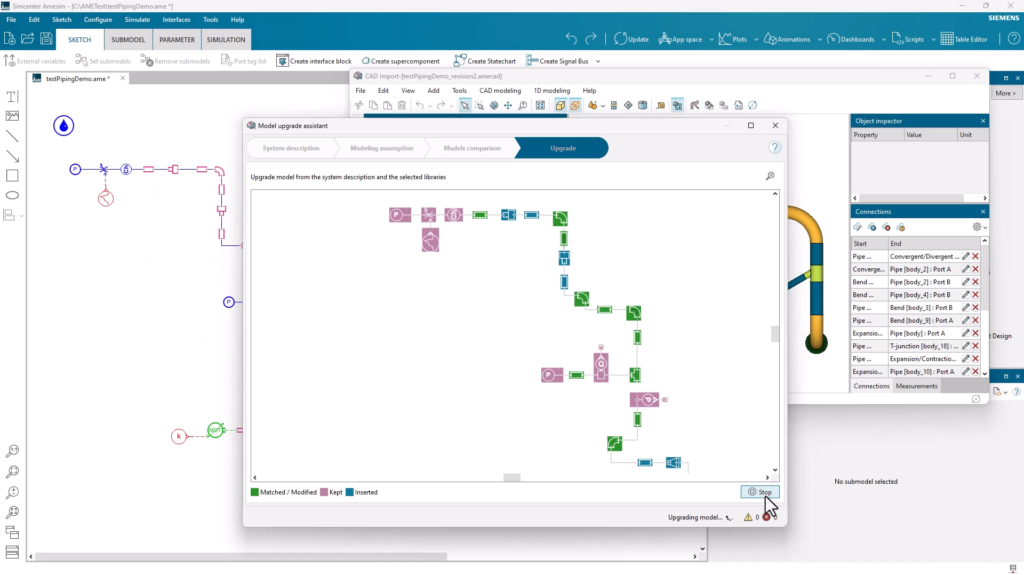

Simcenter Amesim 2310 introduces CAD import sketch generation for pipe handling filling. Engineers can now generate a ready-to-run thermo-fluid model directly from the CAD geometry of a fuel system. This reduces manual steps and model building time, allowing engineers to focus on analysis and explore a wider design space. The capability is aimed at aerospace industry but can be used in other industries like automotive, marine, and energy.

Fluid and thermal applications

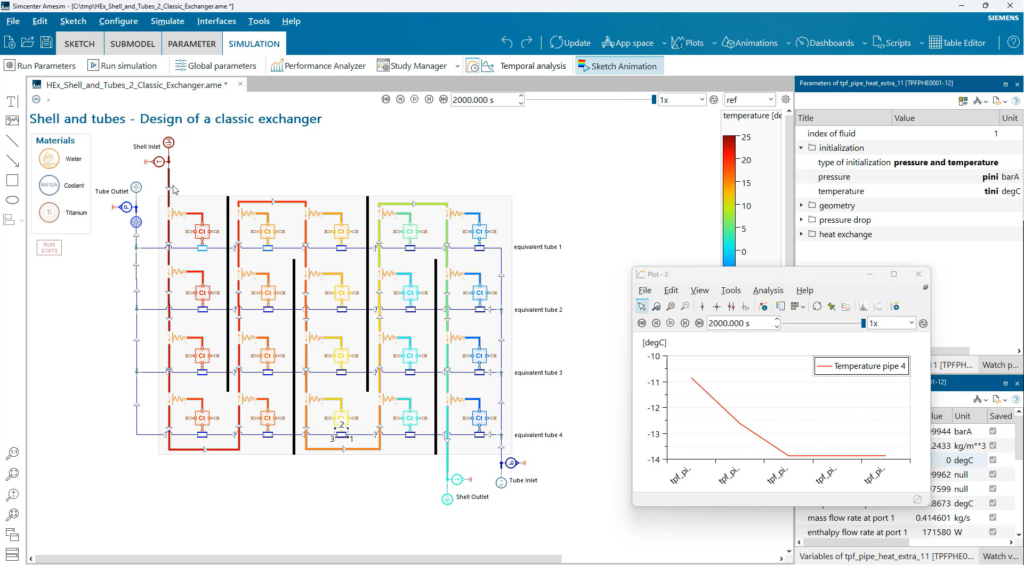

The new extension of the sketch animation in Simcenter Amesim 2310 offers direct analysis of temperature, making it perfect for thermal teams who size or integrate heat exchangers. In seconds, you can visually track the temperature of all constituents of your heat exchangers at all times.

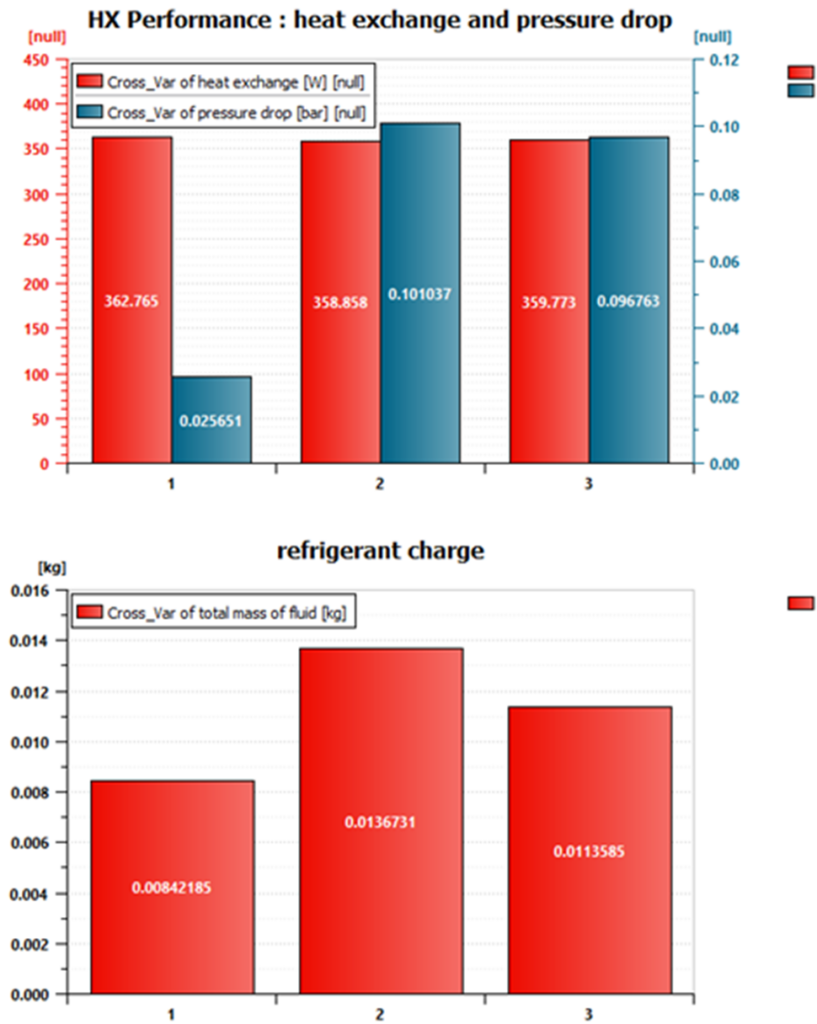

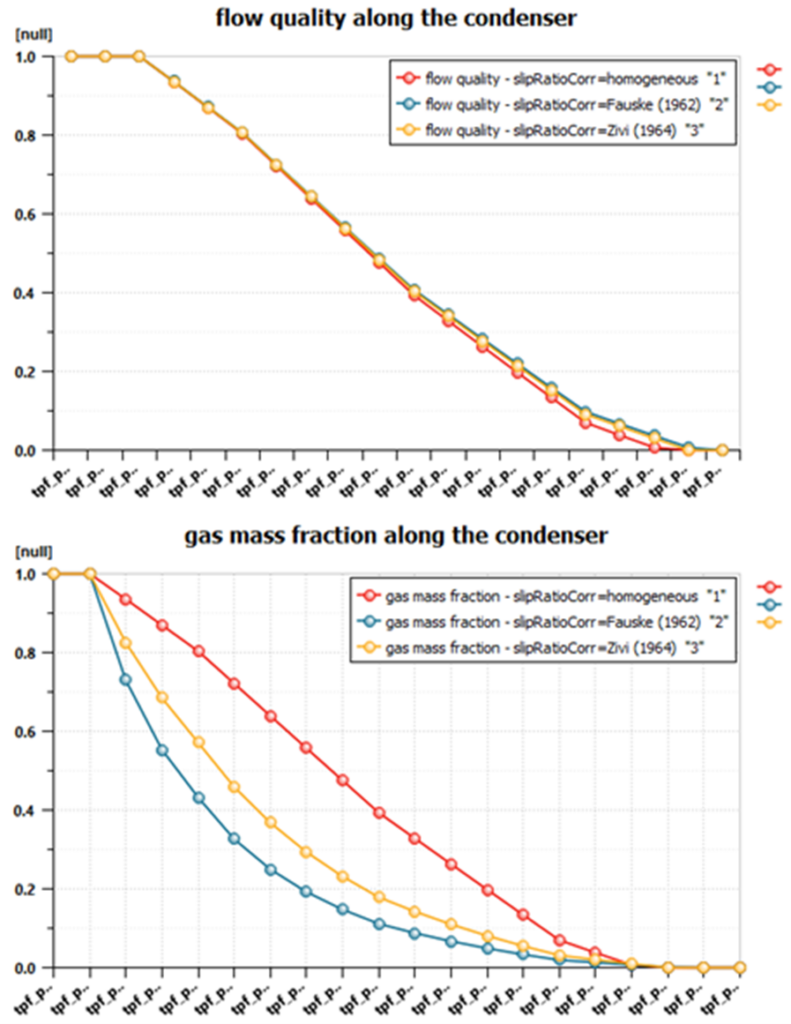

In real-life two-phase systems, it is sometimes possible that the liquid and the vapor phases flow with different velocities. This effect is not captured by a homogeneous model but can have an impact on the performance of the system.

In Simcenter Amesim 2310 we have introduced new slip ratio correlations that offer the possibility to capture differences of velocity between liquid and vapor phase. Using these new correlations together with state-of-the-art heat exchange modeling, engineers can gain predictivity on charge estimation and on pressure drops of their two-phase systems.

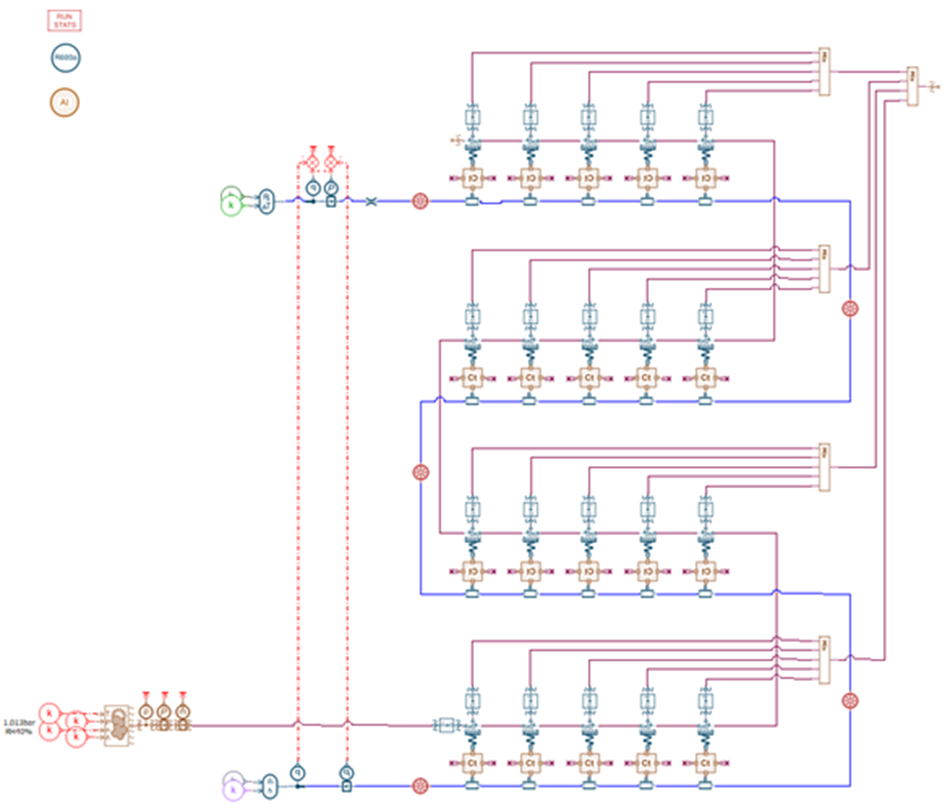

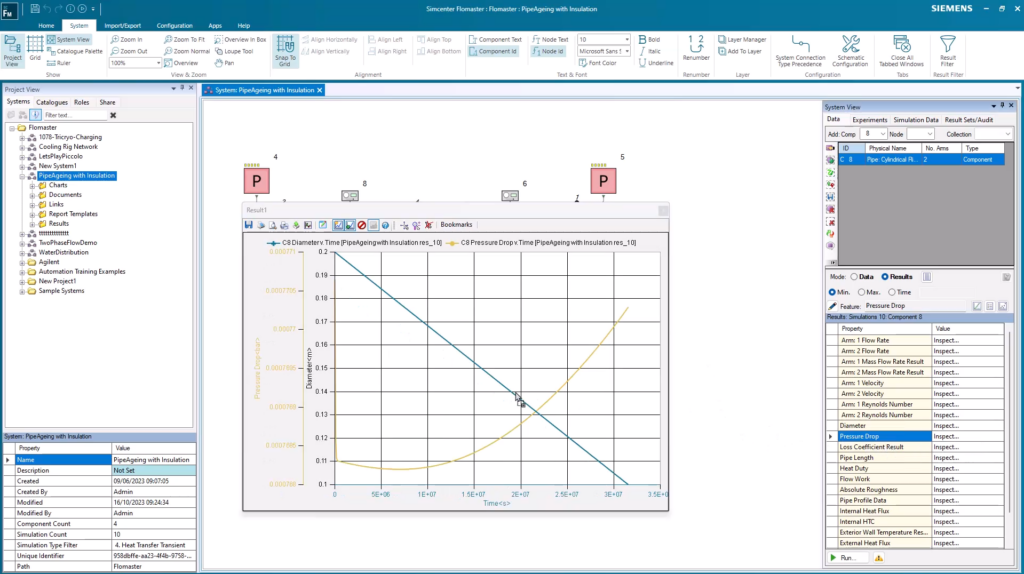

For those in the energy and process sectors, a new pipe aging capability has been introduced in Simcenter Flomaster 2310 to understand solid material deposition changes in the diameter, roughness, and heat transfer behavior over time; helping you identify when maintenance and cleaning are needed to reducing operating costs.

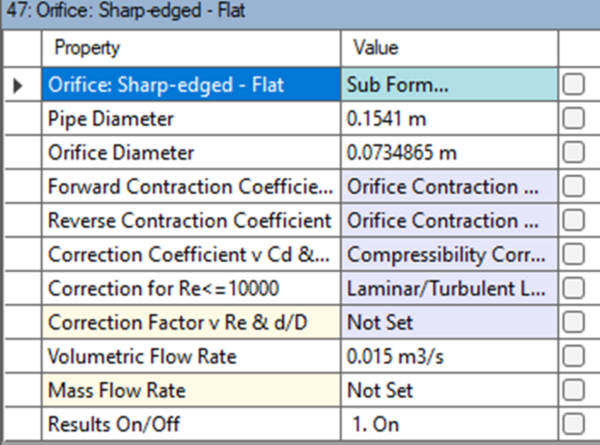

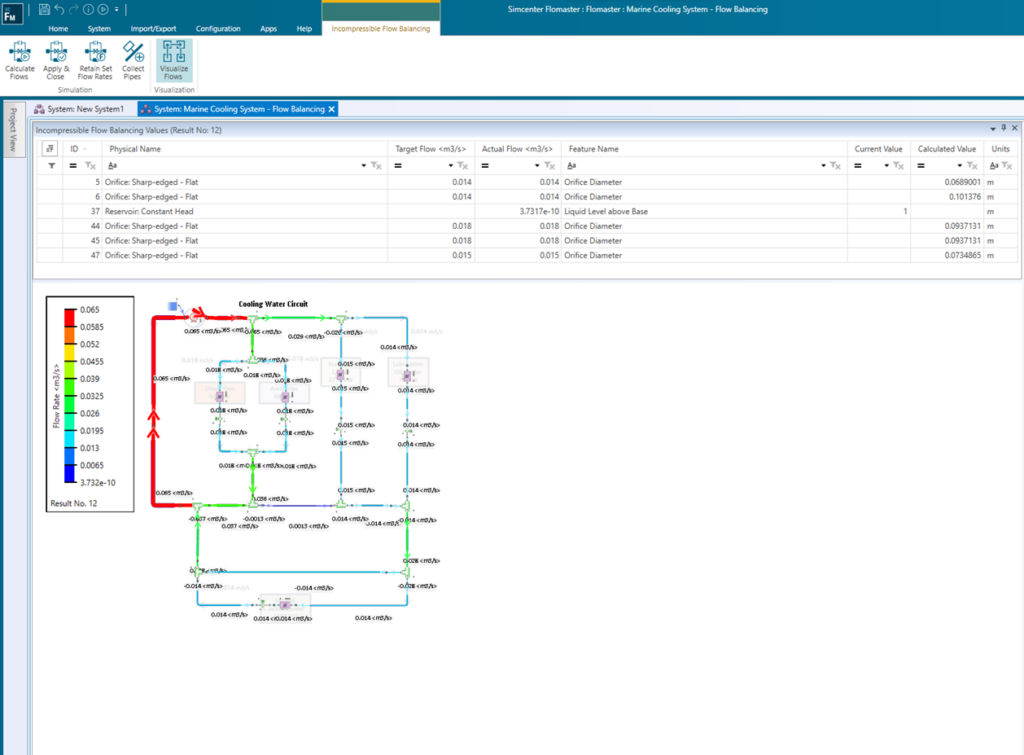

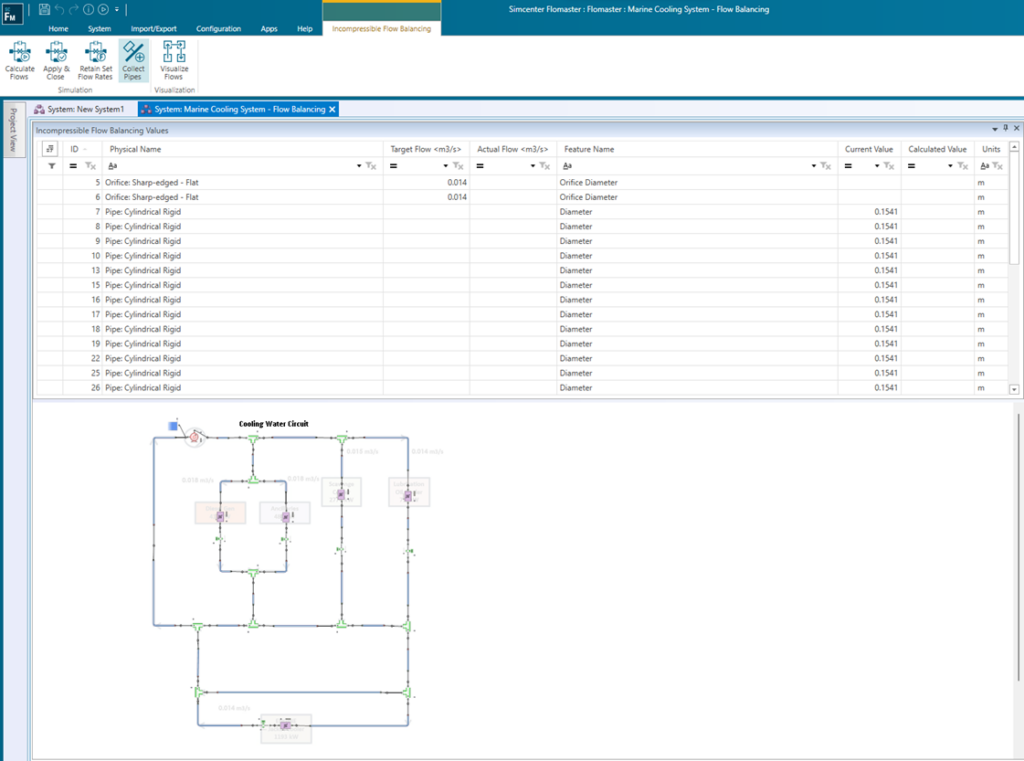

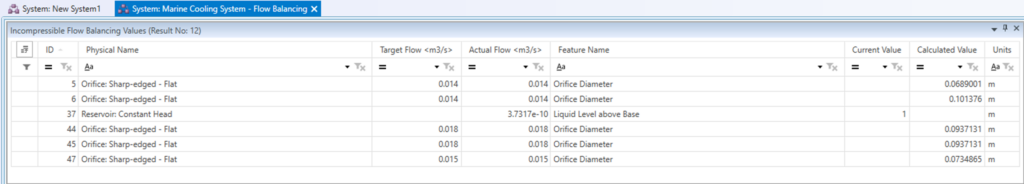

Simcenter Flomaster’s latest update has improved the incompressible flow balancing application, introducing additional components like pipes and constant head reservoir for more options when balancing a system. The flow rate can now be retained and a filter has been added to exclude pipes from view to help focus on critical components. A compressible flow-balancing app has also been introduced. These apps provide an automated workflow for balancing systems more efficiently, enabling easy transition from flow-balancing simulation to static or dynamic simulation.

Platform improvements that increase productivity

Making CAD software and system simulation applications more integrated is key to an efficient digital thread, and the new model upgrade in Simcenter Amesim 2310 offers the capability to apply the design changes from the new 3D CAD parts revision on an existing model improving this process.

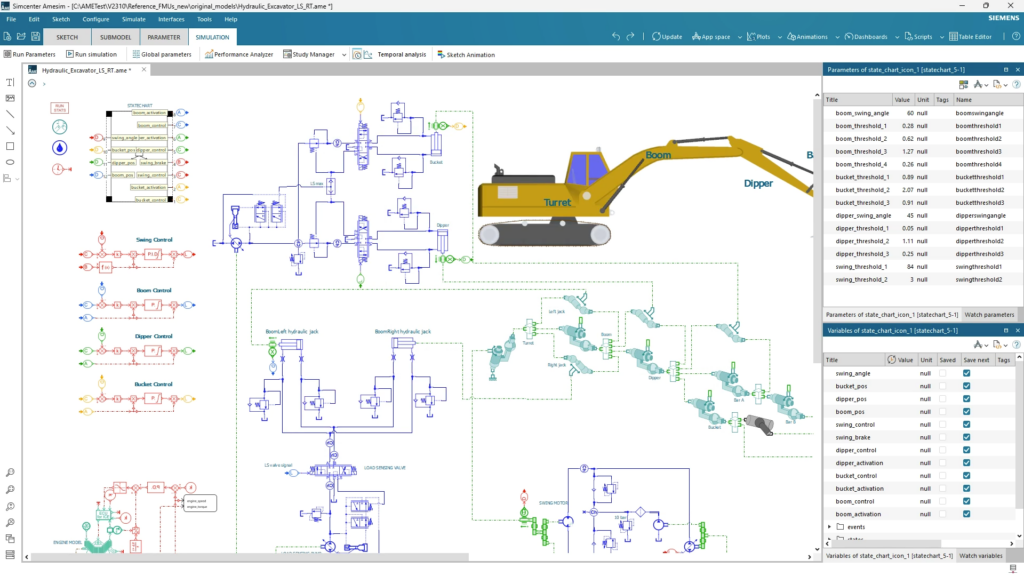

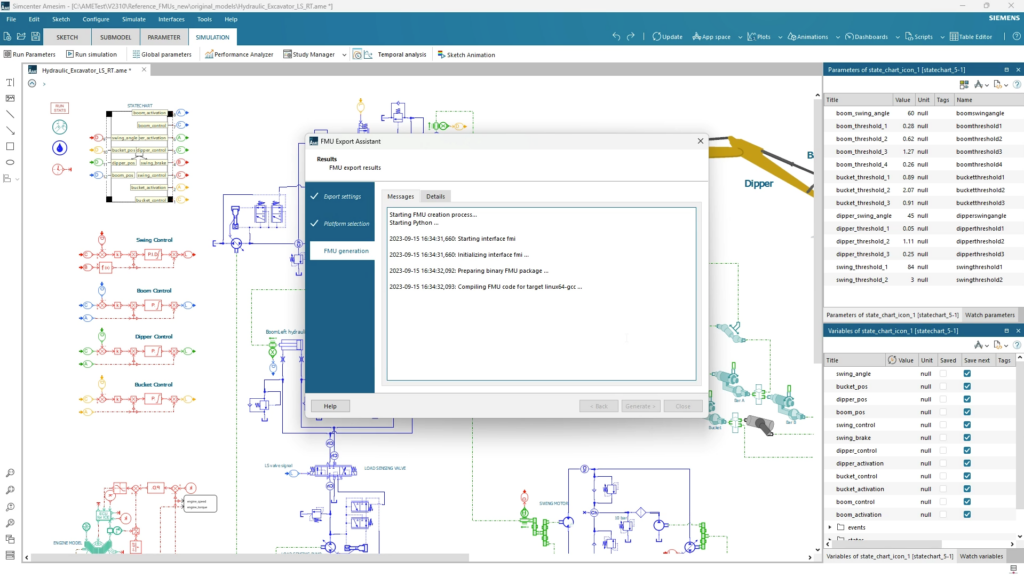

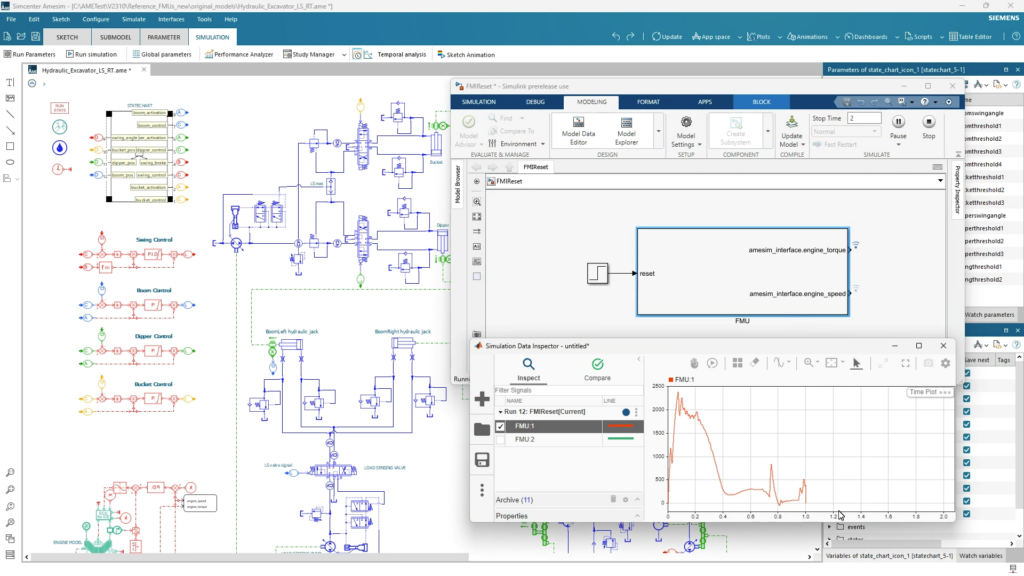

The latest FMI enhancements in Simcenter Amesim 2310 provide strong and reliable initialization capabilities, and also offer a closer connection with machine learning applications. As a result, both experienced and novice users can now make the most out of their Simcenter Amesim models with greater ease.

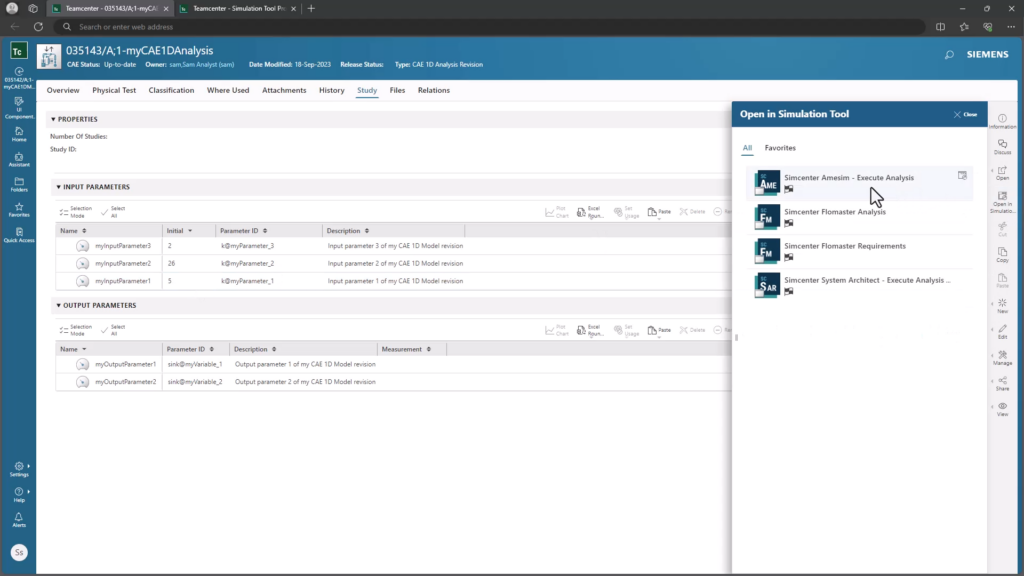

This new release also brings enhancements for Teamcenter connectivity in both Simcenter Amesim 2310 and Simcenter Flomaster 2310. This feature allows requirements management in Teamcenter to be linked with simulation models for easy verification of system requirements.

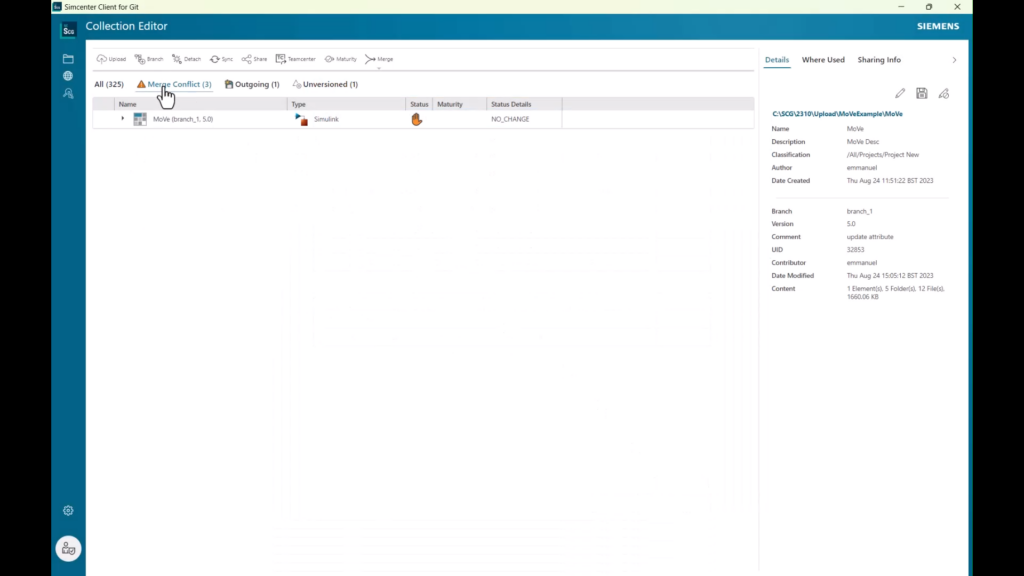

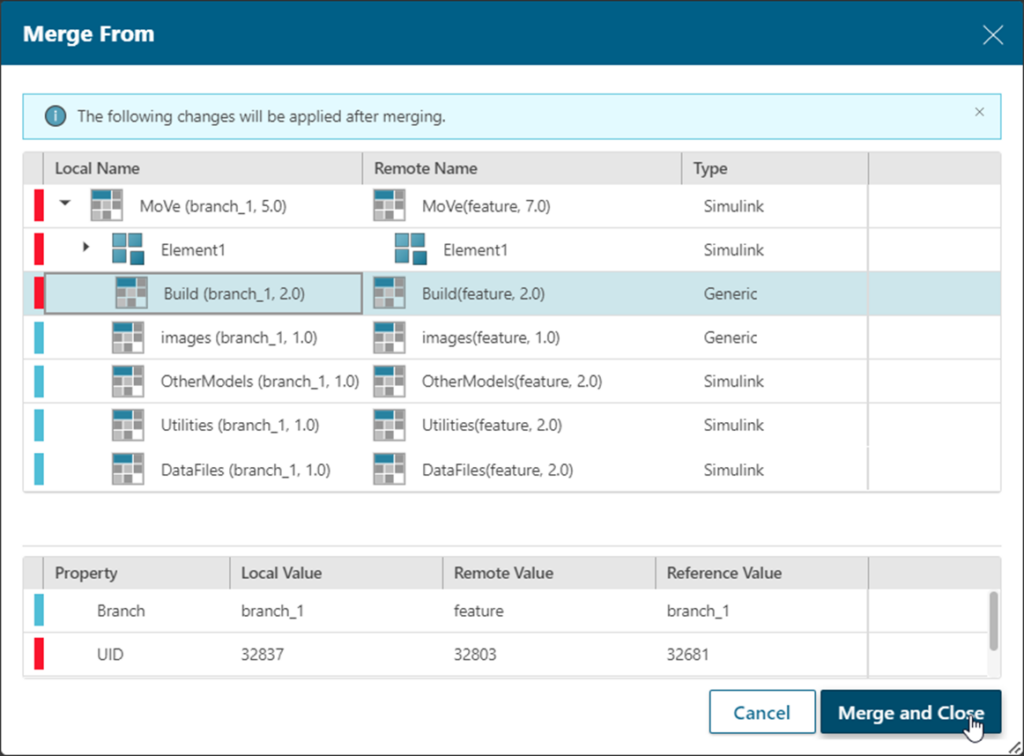

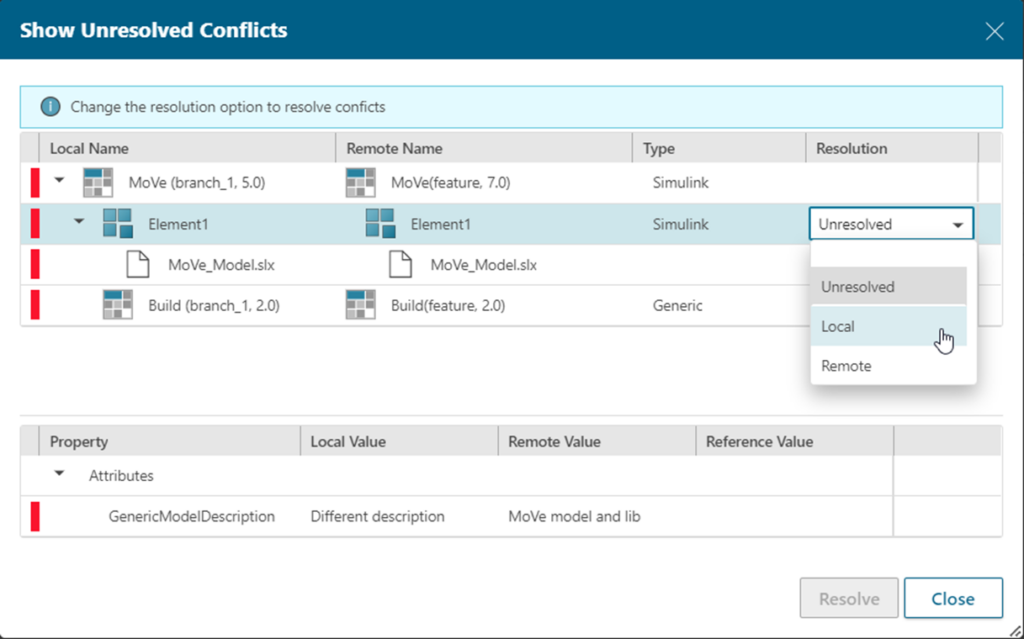

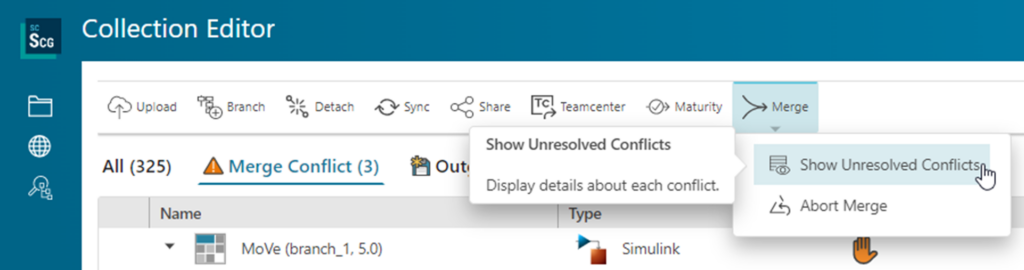

The new Merge with conflicts feature in Simcenter Client for Git is ideal for users working with branches who want to merge modifications from another branch. It offers the ability to resolve merge conflicts manually, making it easy to perform merge for most collection types with or without conflicts.

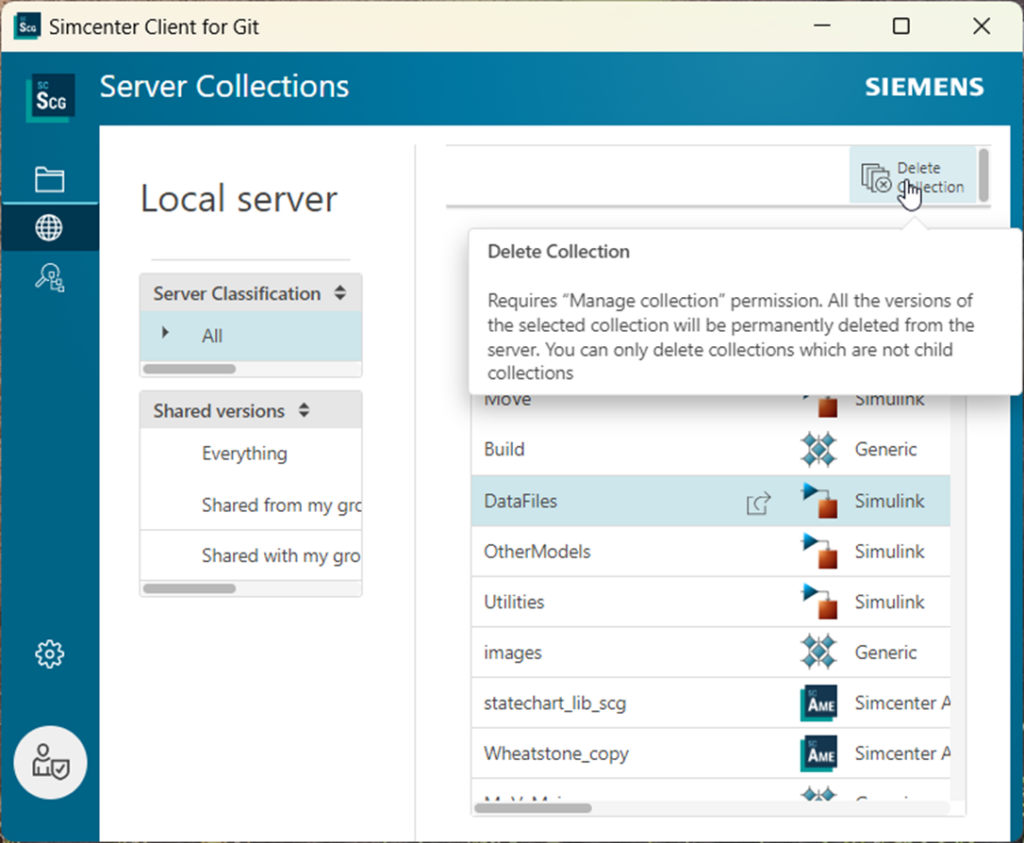

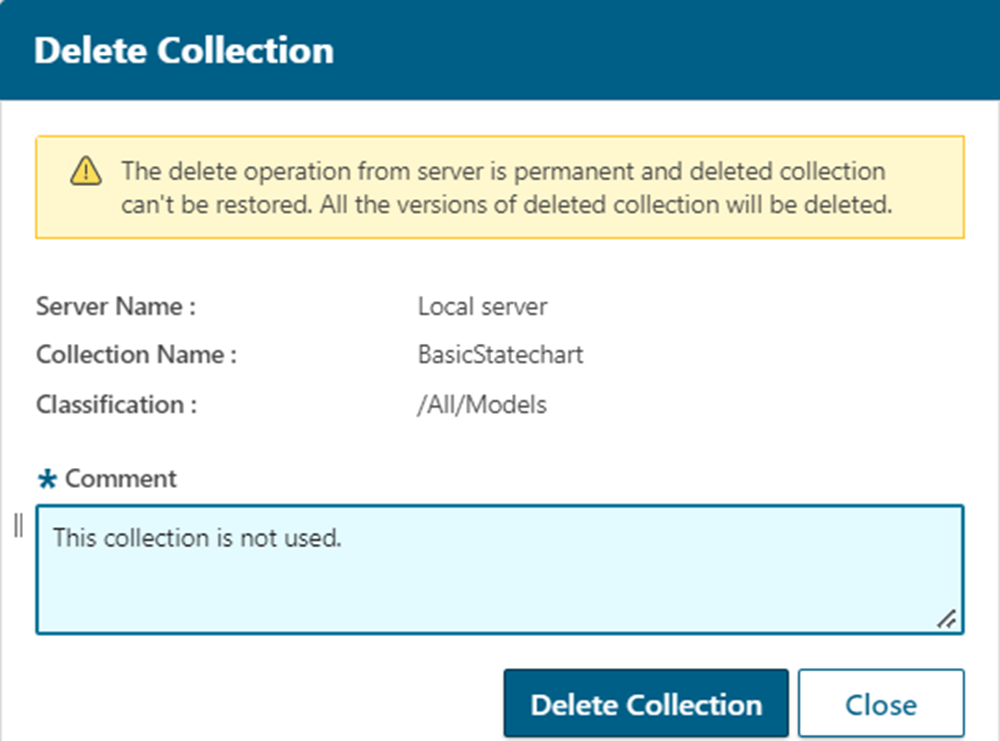

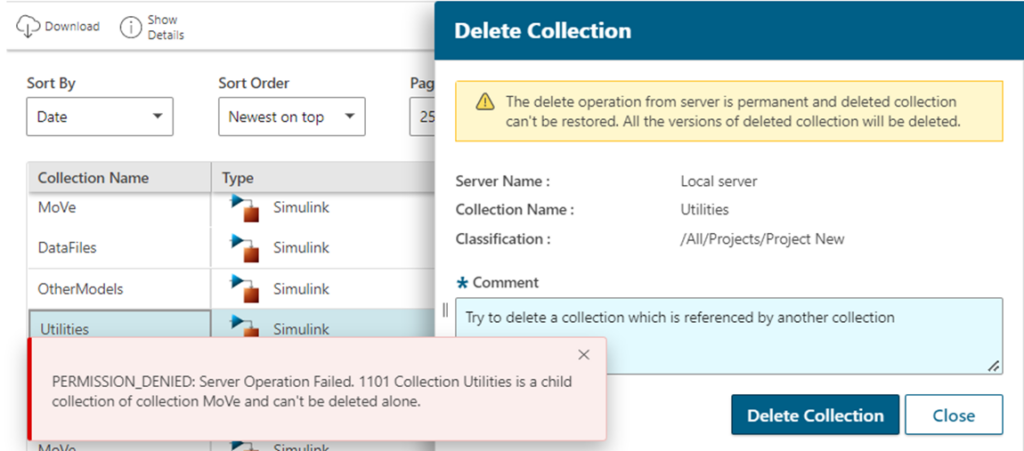

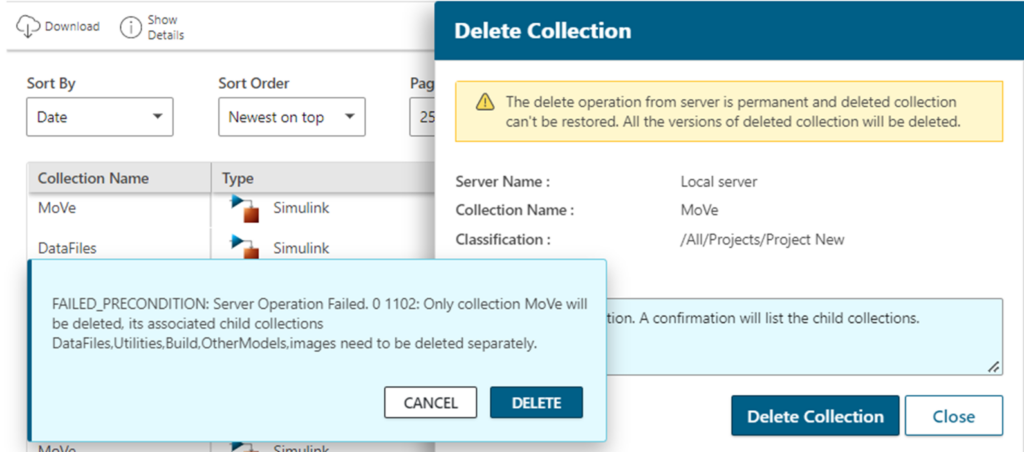

Another improvement in Simcenter Client for Git is what we call Delete collection from server. This new capability allows server administrators to delete unused collections from the server. In this way collections that are not used or that were uploaded by mistake can be removed by users with adequate permissions. Collections can only be deleted when they are not associated to any other collections. This means that it is not possible to delete a collection which is required by other collections.

This article is repubblished from the Simcenter Blog

Deutsch (Deutschland)

Deutsch (Deutschland)  English (UK)

English (UK)